Transformative Ideas for

Shaping Built Environment

Goal

Levery supports players in the Construction Sector

in developing cutting-edge projects with high sustainable impact.

Based on the Open Innovation approach and Applied Research methodology, Levery aims to accelerate the environmental, social, and economic impact of research for shaping a sustainable built environment.

Our Services for Construction Industry

Your journey for your innovation project starts here

NEW PRODUCTS

STUDIO

- R&D Project management

- Product design (eg., DfADRR)

- Research to market

- Market analysis

- Business Model definition

- Pre-commercial validation

- Testing activities

- Communication

SUSTAINABLE

PRACTICES

- Sustainable roadmap

- Decarbonization strategy

- Circular Business Model

- Digital Product Passport

- LCA, s-LCA, LCC, LCI

- ESG - Scope 1, 2, 3

- SRI

EUROPEAN

NETWORKING

- Scouting EU funding opportunities

- Writing funded project proposal

- Open Innovation

- Startups scouting

- Project monitoring and reporting

- Financial management

Recent Insights

Discover all articles in the insight section

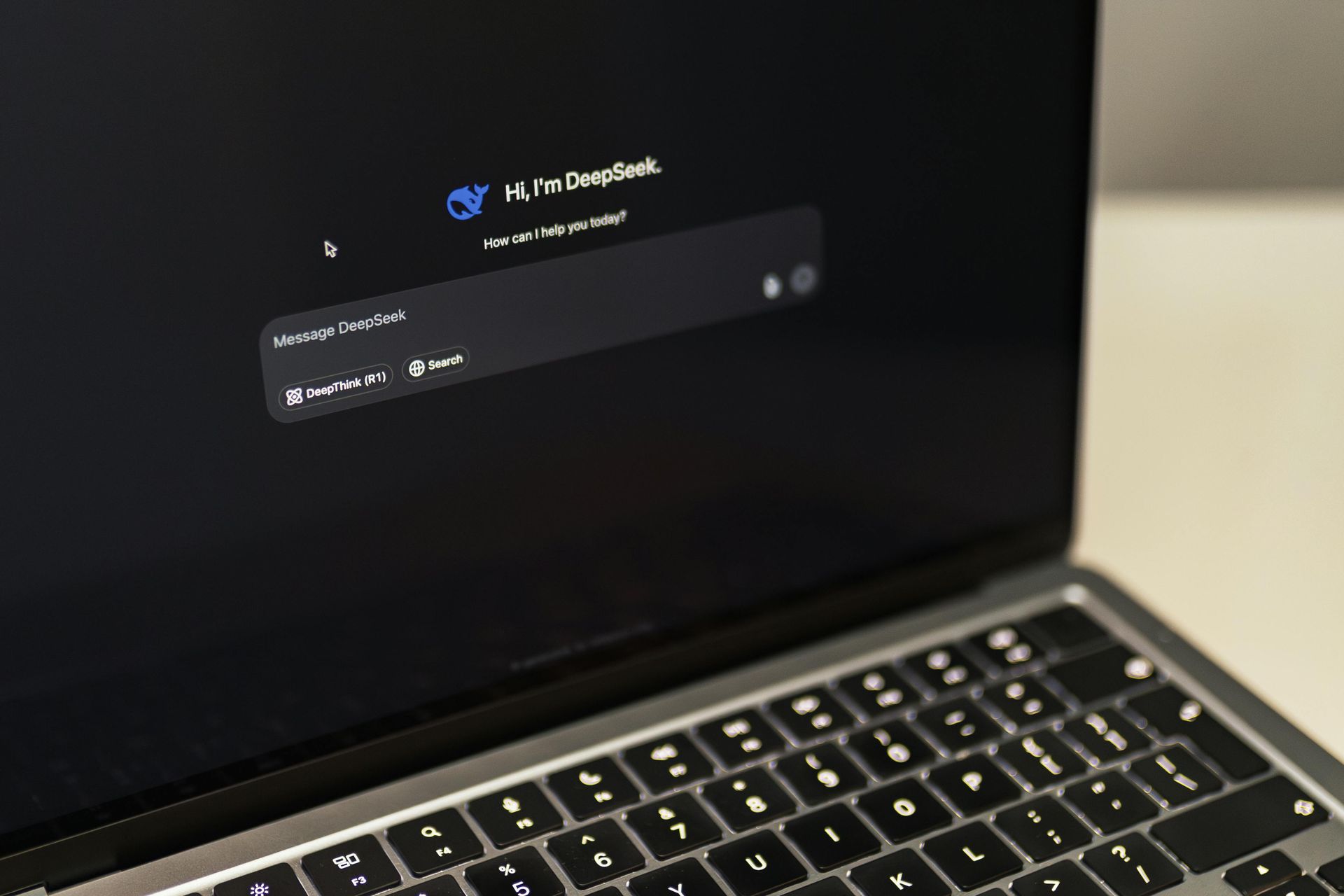

Make It Digital AI Series: Make It Digital AI-01 Article 12/25 AI as a Copilot for Construction: Revolutionizing the Building Sector Value Chain Introduction: The Disruptive Role of AI The global construction industry is on the verge of an epochal transformation, driven by the imperative to increase safety, productivity, and sustainability. This evolution is embodied by Artificial Intelligence (AI), which is rapidly shifting the sector from manual and reactive processes to predictive and optimized workflows. AI is no longer a futuristic concept but a digital copilot that integrates along the entire project lifecycle: from generative design to site management, through to maintenance and energy performance monitoring (end-of-life). Its impact is disruptive: AI can process vast amounts of data (BIM, GIS, images) in seconds that would take weeks manually, significantly improving design accuracy, drastically reducing on-site errors, and the enormous associated material waste. This transition requires a sophisticated Networking Ecosystem, where technology developers, data providers, and end-users (construction companies and design firms) collaborate to validate and scale AI solutions. Key Actors and Stakeholders in the AI Construction Ecosystem The success of AI adoption in construction relies on distinct stakeholders, each pioneering solutions that map directly onto critical phases of the building lifecycle from initial conception to long-term performance. A. Design and Pre-Construction Pioneers These actors focus on the digital planning phase, leveraging AI to automate repetitive tasks, ensure compliance, and streamline data flow before the first shovel hits the ground. Their key contribution is risk mitigation and design efficiency. Design software developers (BIM/CAD integrators): embed AI directly into core design tools, transforming static models into intelligent data platforms that can self-check and recommend optimizations. Digital compliance providers: automate the comparison of design models against complex local and international building codes, eliminating manual checklist processes. Clev: The Intelligent BIM Copilot Clev stands as a BIM/CAD AI copilot dedicated to accelerating project iterations and centralizing complex data management. Its AI capabilities drastically reduce review times (up to 80%) by eliminating the need for hundreds of disjointed plugins. Crucially, Clev automatically performs 100% compliance verification against norms, ISO standards, and client-specific rules. The platform also automates workflows such as Quantity Takeoff (QTO) and leverages an intelligent archive of past projects, moving valuable design knowledge from silos to an actionable, central resource.

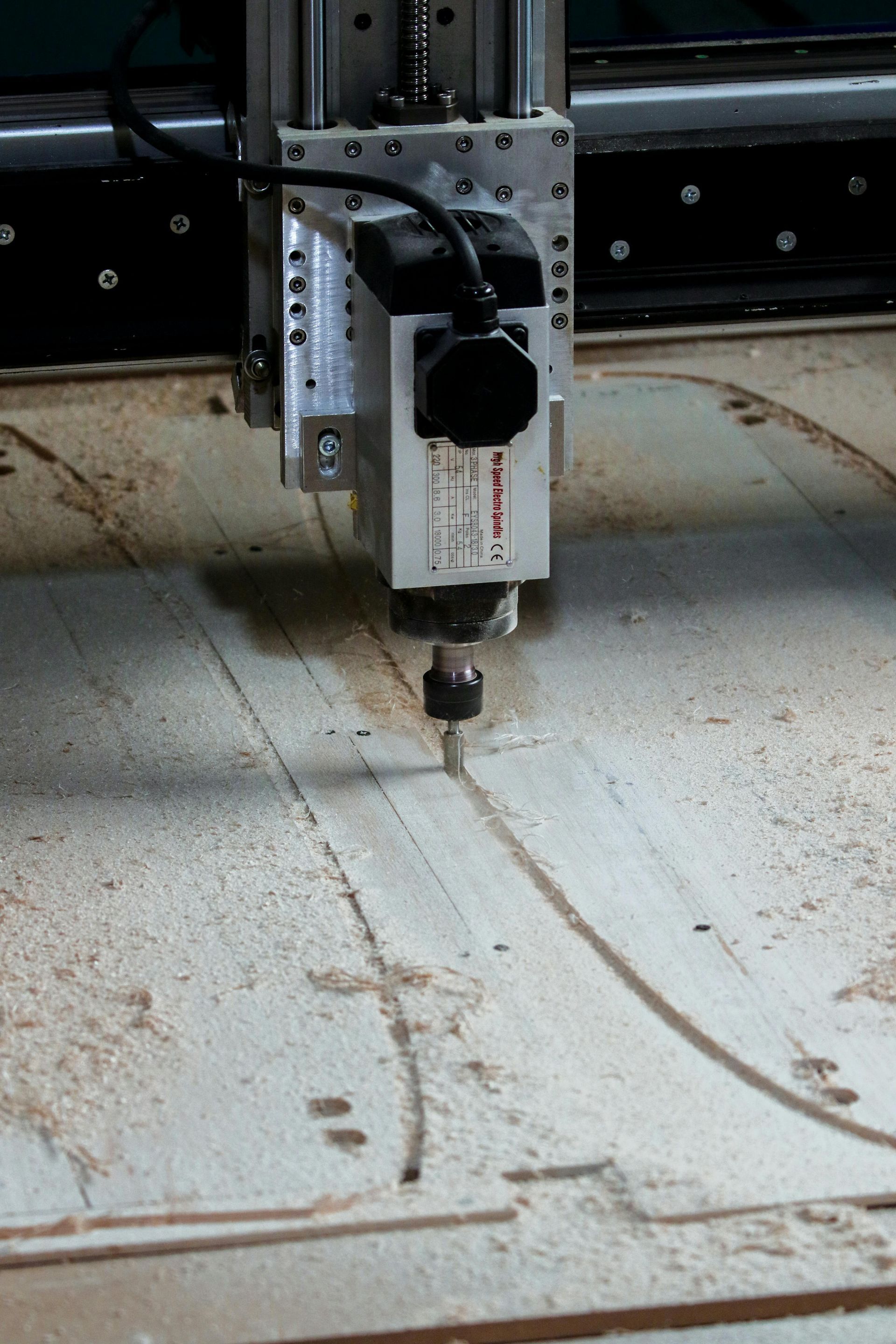

Make It Digital Robot&Automation Series: Make It Digital Rob-01 Article 11/25 Robotic & Automation for Construction: Actors & Stakeholders The global construction industry is actively embracing its next major evolution, driven by the critical need for increased safety, productivity and predictability. This transformation is embodied by the rise of Robotics and Automation (R&A). Moving beyond single-task tools, R&A is integrating into the entire construction lifecycle, from design to execution and monitoring. The success of this shift relies on a sophisticated Networking Ecosystem where technology creators, research entities, large industry players and end-users collaborate to prove the value and scalability of automated solutions. The stakeholders driving this evolution are defined by their unique contribution to bridging the gap between digital planning and physical building. Actors and Stakeholders working along the automation and robotic value chain: best practices The most effective progress in construction robotics is being made by distinct actors specializing in different parts of the digital value chain. Equipment machinery manufacturers: the product innovator This category comprises the companies responsible for productizing specific, high-value robotic applications. A prime example is Hilti Group, a global leader in construction tools and equipment. Hilti’s role extends beyond mere sales; they strategically partner with specialists to industrialize robotic solutions. For instance, the Hilti Jaibot , a semi-autonomous drilling robot, is a result of their long-standing strategic collaboration, which has included work with the Norwegian startup nLink since 2021. This partnership leverages Hilti’s market access and safety standards with nLink’s robotics expertise, successfully automating the strenuous and dangerous task of overhead drilling for MEP installations directly from a digital plan. This synergy demonstrates how incumbents can integrate with agile startups to rapidly scale innovation and immediately improve on-site safety and efficiency.

Make It Green Bio-based Series: Make It Green BIO-01 Article 08/25 Bio-based building materials and products for construction sector: actors and stakeholders The global construction industry is a major contributor to CO₂ emissions and resource consumption. But what if our buildings could actively help us reducing sources consumptions using products from secondary raw materials? That's the promise of bio-based materials, which are derived from renewable biological resources like plants, animals, and microorganisms. These materials can sequester carbon, reduce reliance on fossil fuels, and offer thermal, acoustic, and health benefits for building occupants at least similar to the traditional products. However, the transition from conventional to bio-based materials isn't just about the products themselves. It's about a fundamental shift in the entire value chain, driven by a diverse group of stakeholders. From farmers growing the raw materials to policymakers setting new standards, a collaborative ecosystem is essential for success. This requires setting clear targets and measuring impacts to ensure a sustainable and scalable transition. Actos and Stakeholders working along the bio-based value chain: best practices. Navigating the landscape of bio-based construction requires understanding the key players and their roles. Here are six best practices that highlight how different actors and stakeholders along the supply chain are collaborating to scale up the use of bio-based materials. Raw material suppliers (feedstock processor) A new and critical player in the bio-based ecosystem is the agrowaste player or feedstock processor. These are companies and organizations that specialize in collecting and transforming agricultural by-products, like rice husks, corn cobs, or grape pomace, into usable materials for construction. Crucially, their adoption is boosted by regional innovation anchors like local clusters. A prime example is the Agrifood Clust-ER in the Emilia-Romagna region, Italy. This private association of companies, research centers, and training bodies works to increase the competitiveness of the agri-food sector by connecting its members and focusing on the circular economy and valorization of biomass residues. The impact of this actions can be measured by the tonnage of agricultural waste diverted from disposal (e.g. grape pomace, olive pits) and the volume of new bio-based materials created. The cluster’s direct involvement is measured by the number of joint R&D projects it facilitates that successfully lead to the industrial valorization of agrowaste. At this aim, local clusters create a vital "short supply chain" network that links raw material availability (agrowaste) directly to processing innovation. The Agrifood Clust-ER specifically targets strengthening the resilience of the local bio-economy by identifying new circular production routes (like transforming olive pits into innovative composite materials), effectively turning a regional waste problem into a valuable local resource for the construction sector. With Agrifood Clust-ER and under the coordination of CETMA, Levery is starting a new project of agro-waste chain monitoring.