Digital Product Passport (DPP) Stakeholder Engagement and Actors' Role

Make It Digital

DPP– Stakeholder Engagement and Actors' Role

Series: Make It Digital DPP-01

Article: 02/24

Introduction

The European Commission has recently adopted the Ecodesign for Sustainable Products Regulation (EU, 2024), a regulatory instrument aimed at promoting and harmonizing circular economy practices in the design and production of a wide range of products, including construction products. The regulatory framework, which is expected to be fully adopted by the end of 2024, introduces the concept of the Digital Product Passport (DPP), a digital identity card for products, components, and materials that can store and make accessible detailed information about the product to help stakeholder make decision in adopting circular and informed choices.

What is the state of the art? Who is driving it in the construction sector?

The evolution of DPP and key players

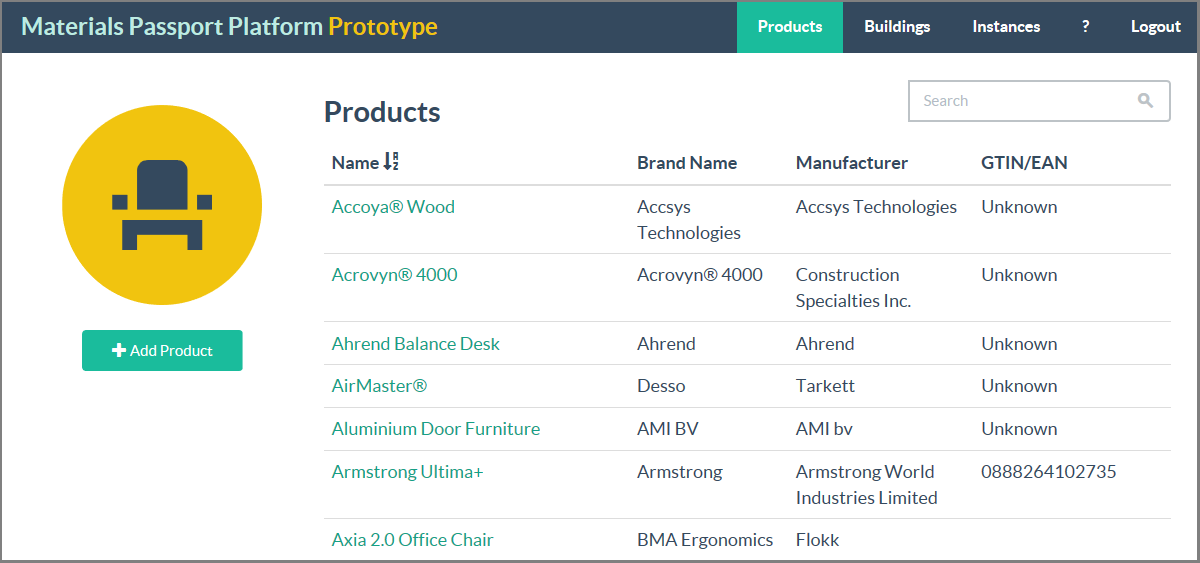

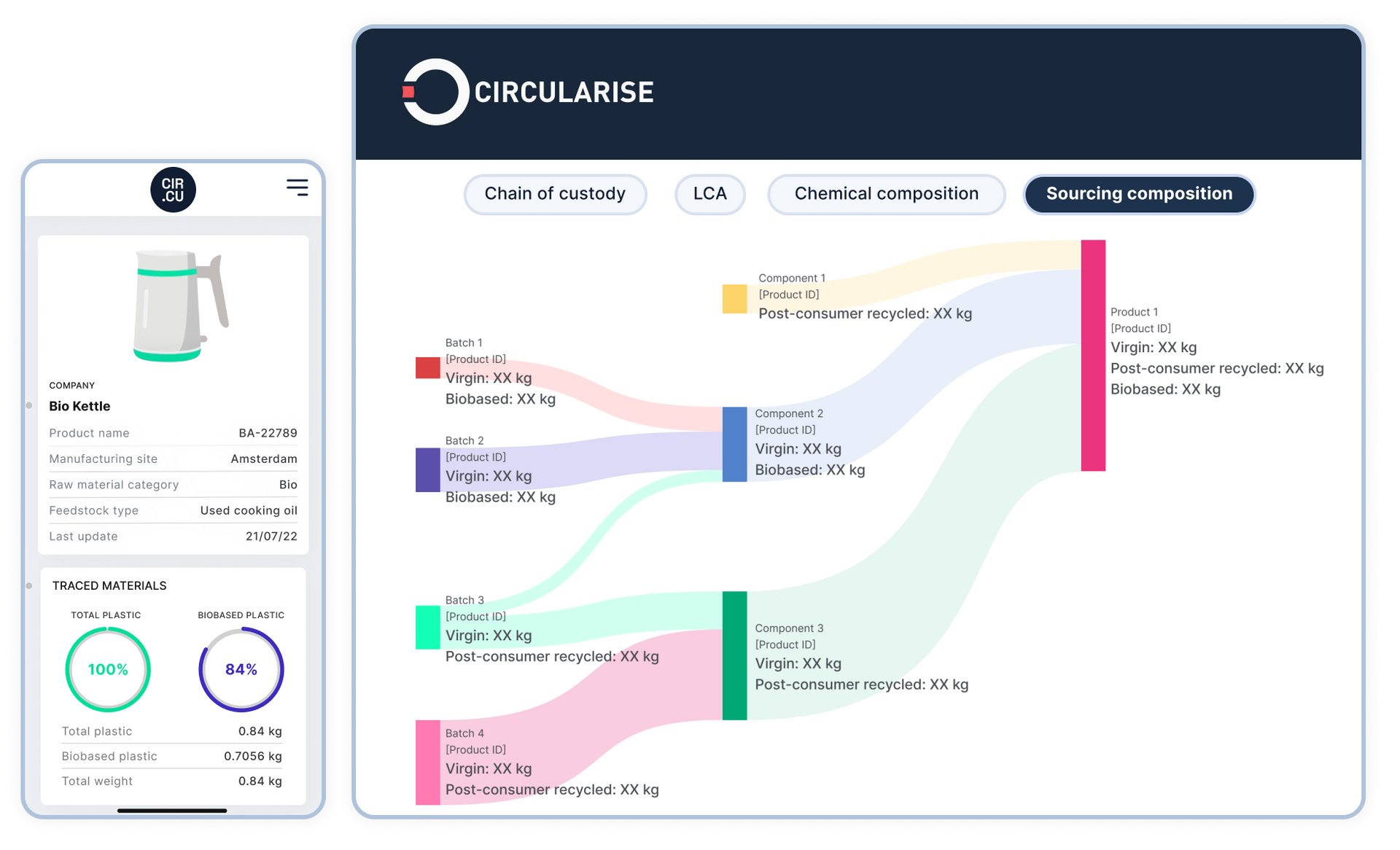

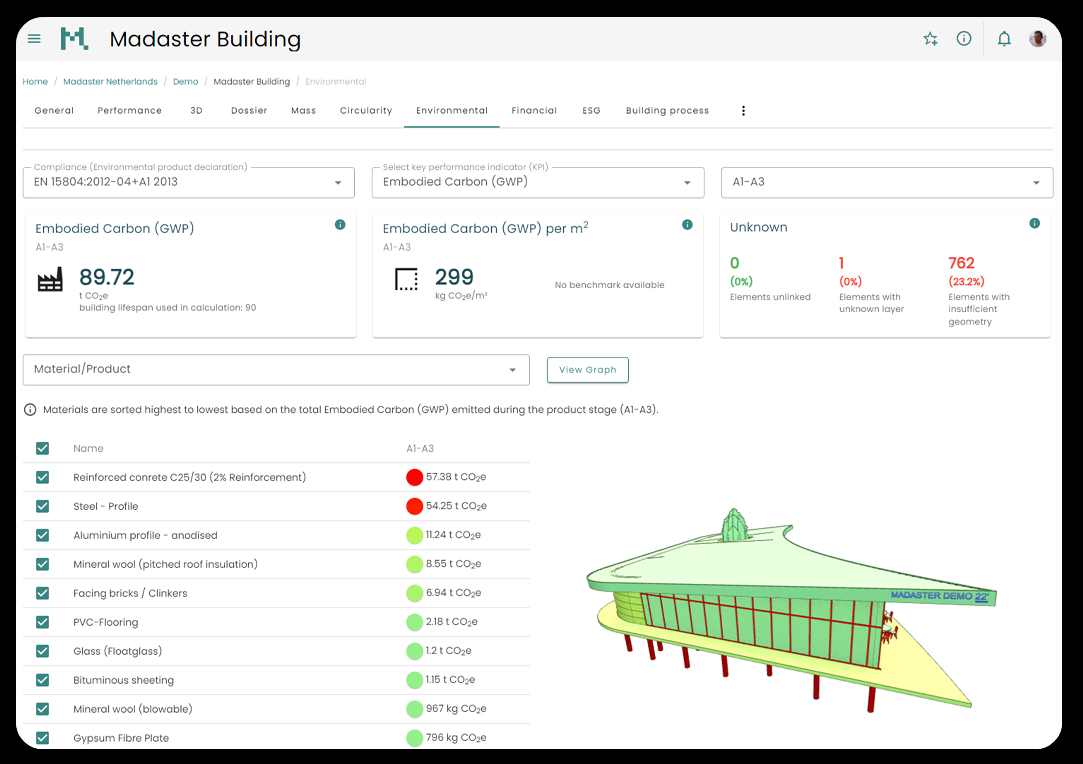

The evolution of the DPP for the construction sector arises from the growing need to track and valorize data throughout the entire life cycle of a building product, with a view to a circular economy and sustainability. A significant precursor was the European BAMB 2020 project (Building As a Material Bank), which pioneered the digitalization of construction materials and the importance of information transparency (Heinrich and Lang, 2020) (Fig. 1). In this context, the concept of Digital Mining emerges, aimed at extracting value from data coming from various sources, such as product technical sheets, environmental certifications, and supply chain information. Platforms like Circularise (Fig. 2) and MADASTER (Fig. 3) are already offering concrete solutions for the creation and management of DPPs, facilitating the collection, analysis, and sharing of data on building products, thus contributing to greater transparency and sustainability in the sector.

Fig. 1 - Material Passport developed by BAMB project

Fig. 2 - Circularise Platform (credit: Circularise)

Fig. 3 - Madaster Platform (credit: Medaster)

Glass industry operators such as Glass for Europe association are actively advancing the integration of sustainability and digital innovation into their practices. Covering a specific manufacturing stage of a building product, Glass for Europe is working to invesgtigate how DPP can support alignment with the EU’s broader sustainability goals, such as achieving a 55% CO₂ reduction by 2030. The adoption of low-carbon technologies and improved recycling methods aligns with their broader mission to contribute to a climate-neutral Europe through advanced glazing solutions that enhance energy efficiency and sustainability in buildings and the Digital Product Passport is studied to foster transparency and circularity in product lifecycle management.

In recent years, Saint-Gobain, a leader in the glass sector and in sustainable building materials in general, has implemented similar innovations by integrating DPP capabilities into its production and product management system, called iWin (Fig. 4). Through its innovative iWin Digital Service, this solution is driving the importance of user-centric digital tools in revolutionising lifecycle management. The platform combines real-time monitoring, data analysis and sustainability-focused reporting, enabling stakeholders to make data-driven decisions on building materials management and performance optimisation. With iWin, Saint-Gobain is demonstrating the need to invest in and highlight the potential of combining advanced glazing technologies with comprehensive digital tools to meet the growing demand for circular and transparent construction processes.

The Institute of Communication and Computer Systems (ICCS), through its i-Sense group, is leading the way in the development of the Digital Product Passport through its participation in several projects such as the DigInTraCE project. These efforts emphasise the use of innovative digital solutions to enable full traceability throughout the product lifecycle. By integrating data from material sourcing to end-of-life, ICCS- i-Sense increases transparency and promotes circularity in the construction sector. The i-Sense Group has been working with various stakeholders to explore how DPP frameworks can support sustainable materials management, including real-time data analysis and compliance with evolving EU regulations.

These contributions as a consortium bringing together research centres, universities and companies at different stages of the lifecycle, alongside the work of other industry stakeholders, underline the collaborative potential of DPP schemes to promote a data-driven approach to lifecycle management. ICCS' active role demonstrates how technology and cross-sector collaboration can address sustainability and circularity challenges, paving the way for smarter, greener construction practices.

Fig. 4 - iWin, RFId tag integrated in IGU (credit: SaintGobain)

Stakeholder roles across the building lifecycle

The integration of DPPs affects stakeholders at every stage of the building lifecycle, shaping responsibilities and actions:

- Design stage

Actors: Architects, engineers and design consultants.

Role: Ensure DPP integration in material selection, with emphasis on environmental compliance and data transparency.

Impact: Facilitates informed decisions on sustainability and material efficiency.

- Production Stage

Actors: Manufacturers and suppliers.

Role: Fill the DPP with comprehensive product details, including environmental performance and circularity metrics.

Impact: Streamlines the supply chain and encourages innovation in eco-design.

- Construction phase

Actors: Contractors, construction companies and workers on site.

Role: Use DPPs to verify material specifications, ensuring compliance and traceability during implementation.

Impact: Improves construction quality and minimises waste through accurate use of materials.

- Stage of use

Actors: Building managers and operators.

Role: Use DPPs to monitor performance, maintenance planning and operational efficiency.

Impact: Extends asset life while reducing operating costs and carbon footprint.

- End of life phase

Actors: Demolition contractors, recyclers and waste management companies.

Role: Use DPPs to identify recyclable materials, enabling effective material recovery and minimising landfill waste.

Impact: Promotes circular economy practices and reduces environmental degradation.

References and Congresses

As the DPP continues to evolve, there are a number of references and key conferences and stakeholder meetings focusing on the Digital Product Passport (DPP) in the construction sector. Some of them.

References

- Heinrich and Lang (2020). BAMB2020. Material Passport - Best Practice https://www.bamb2020.eu/topics/materials-passports/

- From Data Templates to Material Passports and Digital Product Passports

- Giovanardi, M., Konstantinou, T., Pollo, R. and Klein, T. (2023). Internet of Things for building façade traceability: a theoretical framework to enable Circular Economy through life cycle information flows. Journal of Cleaner Production, vol. 382, 135261. https://doi.org/10.1016/j.jclepro.2022.135261

Conferences/fairs

Conclusion

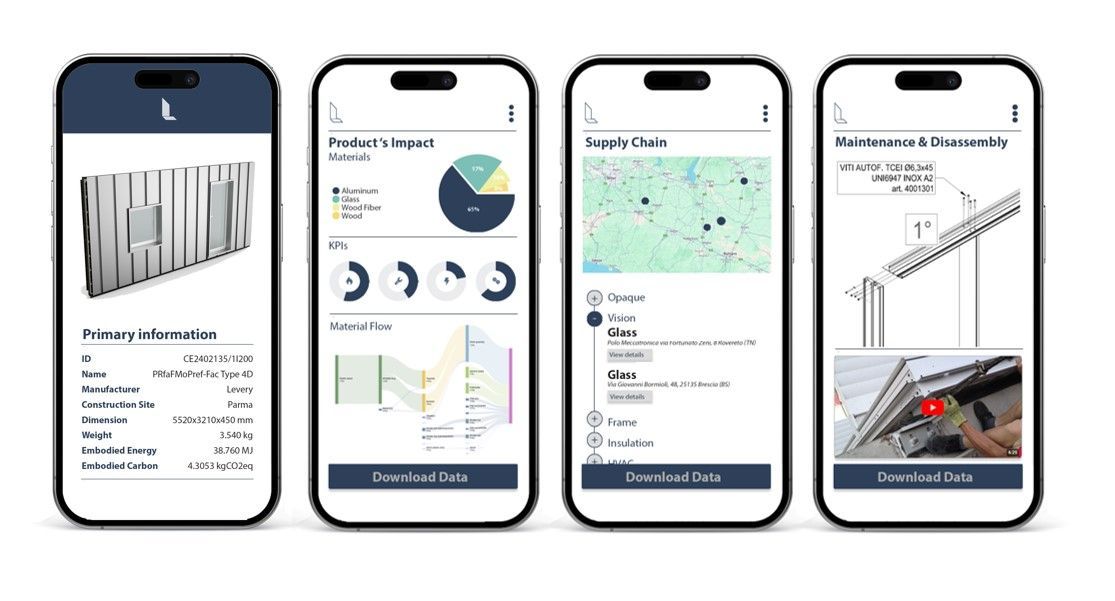

The implementation of Digital Product Passports represents a transformative shift in construction industry practices. The transition to Digital Product Passports represents a paradigm shift in the construction industry, necessitating cross-sector collaboration and technological adoption. Pioneers like Saint-Gobain, ICCS, and innovative platforms such as MADASTER are demonstrating how data-driven approaches can redefine sustainability in construction. As discussed at key congresses and presented in multiple references, the DPP is seen as a critical enabler of a circular economy, allowing stakeholders to manage building materials more effectively. As the regulatory framework solidifies and new players emerge, stakeholders across the value chain must align their efforts to maximize the potential of DPPs, ensuring a more sustainable and resilient built environment.Through collaborative efforts across research institutions, manufacturers, and industry stakeholders, DPPs are driving innovation in sustainability, transparency, and circular economy principles. As the regulatory framework continues to evolve, DPPs will play an increasingly crucial role in shaping the future of sustainable construction (Fig. 5).

Fig. 5 - A Digital Product Passport for facade (credit: Levery)

CALL FOR ACTION

Start your DPP journey today with Levery and exploit the value of product-related lifecycle data of your products. Let’s work together to create new digital services that benefit people, environment and economic.

Contact us now to discuss how we can help you in digitalizing your products and drive the shift toward a greener future.

Levery S.r.l. Società Benefit

info@levery.it

Via Pisino 66, 47814

Bellaria Igea Marina (RN), Italy

P.IVA 04730050400

All Rights Reserved | Levery Srl Società Benefit